DTF Printing Proficiency: Raise Your Textile Creations with Direct-to-Film Innovation

Ultimate Overview to DTF Printing Techniques for Magnificent Textile Layouts

Starting the trip of mastering DTF printing strategies can open up a globe of opportunities for creating aesthetically exciting fabric layouts. As the textile sector proceeds to advance, remaining in advance of the curve with innovative printing approaches is essential. In this guide, we will check out the detailed details of DTF printing, from comprehending the basic basics to unraveling advanced shade strategies that can boost your styles to brand-new elevations. Remain tuned as we look into the subtleties of selecting the ideal products, refining the printing process, and getting rid of common difficulties to attain spectacular results.

Understanding DTF Printing Essentials

DTF printing, a process that includes moving styles from an unique film to textiles utilizing warmth and stress, creates the structure of fabric printing strategies. The very first step in DTF printing entails developing or picking a layout that will be printed onto the fabric.

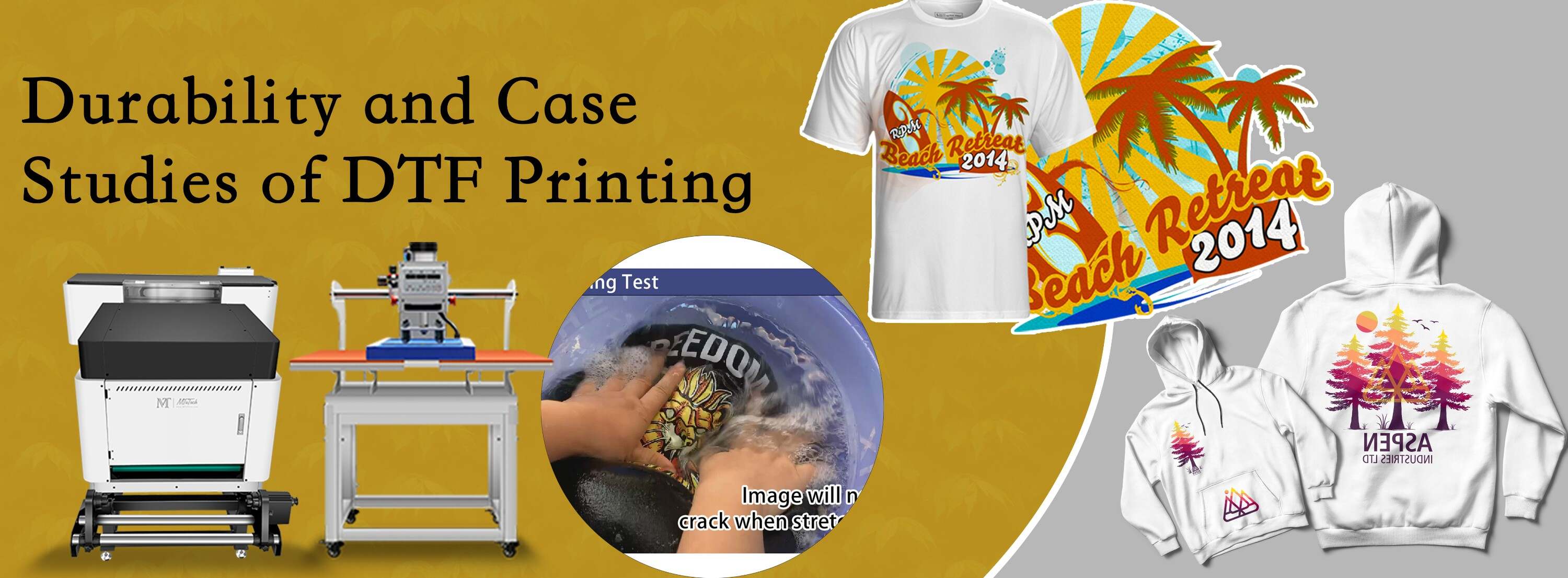

When the style is printed on the movie, it is then very carefully positioned onto the material, guaranteeing proper positioning and positioning. The following crucial step involves using heat and stress making use of a heat press maker. This process activates the dyes or pigments on the movie, causing them to sublimate and bond with the fabric fibers completely. The result is a magnificent, durable textile style that is cleanable, versatile, and resistant to fading. Generally, recognizing the essentials of DTF printing is essential for grasping this modern textile printing technique.

Picking the Right Fabric Materials

Having developed the foundational concepts of DTF printing methods for fabric styles, the next crucial consideration lies in choosing the suitable fabric products to enhance this cutting-edge process effectively. Additionally, the stretchability of these materials can suit the heat transfer process involved in DTF printing without misshaping the design. By selecting the appropriate fabric products, developers can make the most of the capacity of DTF printing to produce resilient and spectacular textile designs.

Mastering the Printing Refine

To master DTF printing methods for textile layouts, understanding the printing process is important for achieving premium and regular results. The printing procedure in DTF includes several crucial steps that call for accuracy and focus to detail. First of all, preparing the artwork for printing is vital. This includes making sure the design is properly sized and placed for the fabric. Next off, the layout is published onto an unique DTF movie making use of a compatible printer with the ideal settings to accomplish optimal color vibrancy and quality (DTF Printing). Once the layout is published, it is then transferred onto the material utilizing a warmth press maker. The temperature level, stress, and period of warm application must be very carefully controlled to ensure correct attachment of the layout to the fabric. Furthermore, grasping the peeling process after heat pressing is essential to protect against any type of damage to the layout or material. By sharpening each of these steps in the printing process, designers can regularly produce sensational and sturdy fabric designs with DTF printing techniques.

Enhancing Designs With Shade Methods

In addition, trying out color gradients can why not find out more bring a feeling of activity and fluidity to the style. By mixing shades perfectly, a gradient result can be attained, including a vibrant and modern touch to the textile style. Additionally, using color blocking methods can create strong and striking visuals by comparing various strong colors in distinct areas of the design.

Furthermore, including metallic or neon colors can provide a distinct and eye-catching component to the fabric style, making it stick out and show a feeling of vibrancy. When purposefully used, these color strategies can boost the total visual charm of textile designs, making them extra captivating and unforgettable.

Troubleshooting Common DTF Printing Issues

After discovering different shade methods to enhance textile styles, it is important to resolve usual DTF printing problems that may arise throughout the manufacturing process. Furthermore, issues with picture clearness and sharpness can occur due to low-resolution images or incorrect printing methods. By being aware of these typical problems and implementing the required troubleshooting actions, you can improve the overall top quality of your DTF printed fabric designs.

Final Thought

In final thought, understanding DTF printing techniques is crucial for creating stunning fabric Related Site styles. With practice click for more and interest to detail, one can develop gorgeous and distinct fabric layouts using DTF printing strategies.

Styles))))

DTF printing, a process that entails transferring layouts from a special film to fabrics utilizing warmth and stress, creates the foundation of textile printing methods.Having actually established the fundamental concepts of DTF printing strategies for textile designs, the next important consideration lies in selecting the ideal textile products to enhance this ingenious procedure efficiently. By choosing the right textile materials, designers can maximize the capacity of DTF printing to produce resilient and sensational fabric layouts.

To excel in DTF printing techniques for fabric styles, grasping the printing process is important for attaining regular and high-quality results. DTF Printing. By sharpening each of these steps in the printing process, developers can regularly create resilient and sensational textile designs with DTF printing techniques